This article will be primarily geared toward the use of these pumps in 7.3L and 6.0L Powerstroke Diesel vehicles, since that's what we are most known for, and it is what we've spent the most time supporting in the diesel fuel system world.

This article will be primarily geared toward the use of these pumps in 7.3L and 6.0L Powerstroke Diesel vehicles, since that's what we are most known for, and it is what we've spent the most time supporting in the diesel fuel system world.We've been selling one or the other of these pumps for a lot of years now. We've seen the evolution of both product lines, from low pressure helper pumps that remove air and feed the OEM lift pump to todays higher pressure units that remove air while replacing the OEM lift pump. We experienced the growing pains and problems that both lines had as they moved from low to high pressure, made other design changes or in some cases as the company changed ownership. The past aside, we are happy to say that todays products are the most solid offerings we have ever seen from both companies, and we are proud to sell and install them both for our customers.

That said, we do get asked by customers if we have a brand preference or what the differences are between the two different brands, so I figured this would be a good way to address those questions. For the purposes of this discussion, I will limit my comparison to the Current FASS Signature Series 140G (TSF1x180F140G) pump and the Current AirDog II-5G (A7SABF59x) pump, as these are the most commonly used models and are a good direct comparison. FASS does offer higher volume pumps for higher HP builds. AirDog does NOT offer any larger pumps.

Both of these pump systems offer a similar list of features:

- Air Removal with Aerated Fuel Returned to Fuel Tank

- Integrated Fuel Pressure Regulator (part of Air Return)

- Pre & Post Pump Fuel Filtration with Water Separation *

- Spin-On Cartridges for Easy / Cost Effective Service

- Vehicle Specific Installation Hardware

- Increased Flow Volume over OEM Lift Pump **

- Limited Lifetime Warranty (Timely Product Registration REQUIRED!)

** Supports Larger Than Stock Fuel Injectors

These systems do have some differences that are worth noting as well.

- Fuel Pressure Regulator Differences:

- FASS - Until about 2021, FASS pumps used a simple spring loaded ball as their fuel pressure regulator. The ball would close the fuel return back to the fuel tank, forcing all of the fuel out the engine port, until the pressure reached the desired level. Once the pressure was high enough, the ball is forced off the seat and air/fuel return to the fuel tank, providing both the air removal and outlet fuel pressure management. Some time after releasing the Titanium Signature Series update to their product line, the ball was replaced by a machined aluminum poppet (referred to as the "Flow Through Regulator" by FASS). FASS says that this regulator upgrade results in more consistent fuel pressure.

- AIRDOG - In the early years, including the earliest high pressure versions, AirDog used a spring & ball configuration like FASS. If I'm remembering correctly, the 4G model was the first to get their adjustable regulator with the "Demand Flow" system. The Demand Flow system features an internal passage that allows fuel to flow from the pressure side of the pump back to the suction side of the pump, reducing the amount of fuel returned to the tank. The original 4G adjustable pressure regulator design did require maintenance after a while. Customers would experience a drop in output pressure, and adjusting the regulator didn't fix the problem. Removing the regulator, cleaning it up and replacing all of the o-rings will return the regulator to working condition for a period of time. The latest 5G versions of the AirDog pump features a diaphragm style regulator that has addressed the maintenance issues from the 4G pump, and also appears to be doing a better job of pressure management than the 4G did.

- Fuel Filter Differences:

- FASS - For many years, FASS pumps ran the water separator on the suction side of the pump, and the small micron filter on the pressure side of the pump. Their current Titanium Signature Series pumps are running a looser suction side filter (easier priming but still protects the pump) along with a small micron filter on the pressure side that also includes water absorption. Since we have not tested this ourselves, we can only go by the data that FASS has put out, which states that their Xtreme Water Separator technology is superior to their old filter configuration, and to the current filter configuration of their competitor.

- AIRDOG - Todays AirDog pumps are running the water separator on the suction side of the pump, and the small micron fuel filter on the pressure side of the pump, similar to most other fuel system competitors on the market, and similar to how FASS used to do it.

- THIS VIDEO shows a water removal comparison between FASS and AirDog. It is from a FASS booth at a tradeshow, so it is certainly biased toward FASS, but at this time I haven't seen anything to suggest it was not accurate.

- Flow Rating Differences:

- FASS - This pump is currently listed as 140 gallons per hour at 60-65psi on the FASS website. More on this below.

- AIRDOG - This pump is currently listed as a 165 gallon per hour pump (pressure not specified) on the AirDog website. More on this below.

- Replacement Fuel Filters:

- FASS - Since FASS updated their filters to the new configuration with the water removal on the pressure side, there are no cross-reference filters from other manufacturers available.

- AIRDOG - The AirDog website lists cross-reference numbers for filters from NAPA, WIX, Baldwin and Fleetguard.

- Other Minor Differences:

- There are slight differences in the physical size of the units.

- The units mount to the vehicle differently, so it may be worth reviewing the installation instructions if you are concerned about physical space constraints.

- Depending on the installation, one may hang lower than the other.

With regard to the Fuel Flow and Pressure Rating specs of both of these pumps, we do have some first hand test information that we want to share. It should be noted that this information is not presented to make either product look better or worse than the other, or to "call them out", just to clarify what we have seen in "Real World Use" and how it relates to what we've seen when testing these pumps on our flow bench. Over the years, we have taken MANY tech support calls for our Regulated Return products being used in conjunction with both FASS and AirDog pumps, so we've learned how to get them to play nicely together. With the exception of the times we needed to tell an AirDog 4G customers that they needed to take the regulator in their pump apart and service the o-rings, getting the pressure set correctly with either AirDog 4G or 5G pumps was generally easier because it was simply a matter of turning a set screw. FASS situations aren't really any more difficult, outside of the fact that we frequently needed to tell the customer that they needed to upgrade the regulator spring (purchase and wait for delivery) to get their desired pressure.

That said, there have been some real head scratchers over the years...enough that when we built our fuel pump flow bench, we decided we needed to include the FASS and AirDog products in our testing. When we first built the bench, the AirDog 4G pump was on the market, so we ordered one of those and a FASS 140G from our distributor. By the time we were most of the way through our list of a bunch of different pumps to test, AirDog had released their 5G pump, so we had to get one of those to test as well. By the time it was all said and done, we tested both AirDogs (4G and 5G) as well as (2) of the FASS 140G pumps (one we purchased, one sent to us by a customer that was having issues nobody could resolve). All of the FASS and AirDog pumps were tested with their regulators configured for 75psi operation, the same way we run them in trucks with our regulated return ("real world" configuration with 10psi of "overhead"). In the case of the AirDog pumps, this means that we adjusted the built in regulator to reach a max of 75psi at the external pressure regulator (simulated Regulated Return). For the FASS pumps, we installed the 75psi spring we get from FASS for use with Regulated Return kits. This should should set the regulator in the FASS to 70-75psi, giving us 5-10psi of overhead with the engine regulator dialed down to 65psi. Once the base pressure of the pump was set, we adjusted the external regulator in 5psi increments, starting at 0psi, until the flow volume tanked.

The FASS pump that we purchased for testing was run for 44 hours on the bench before the flow testing, per comments by FASS regarding break-in of the electric motor.

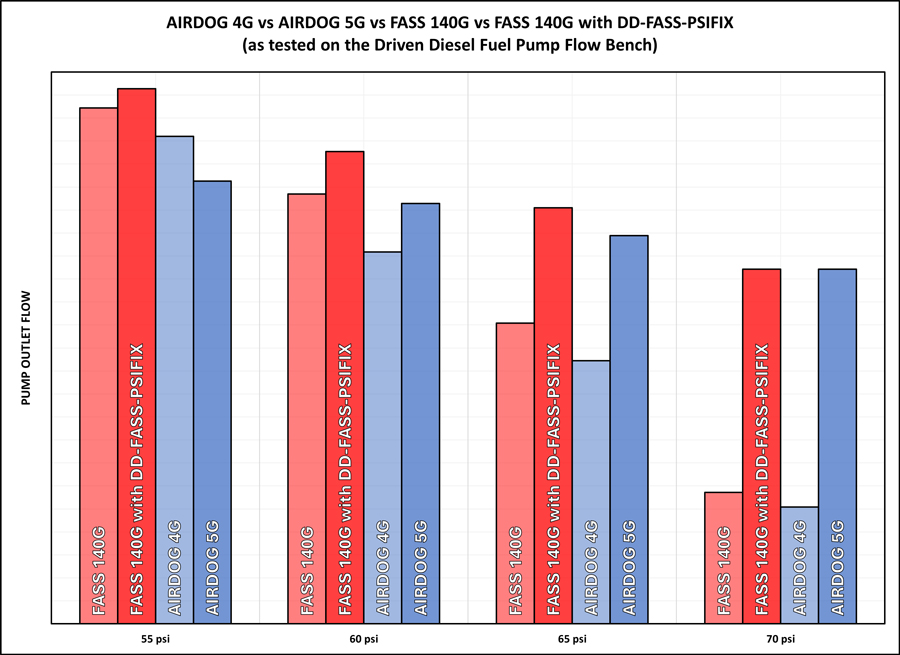

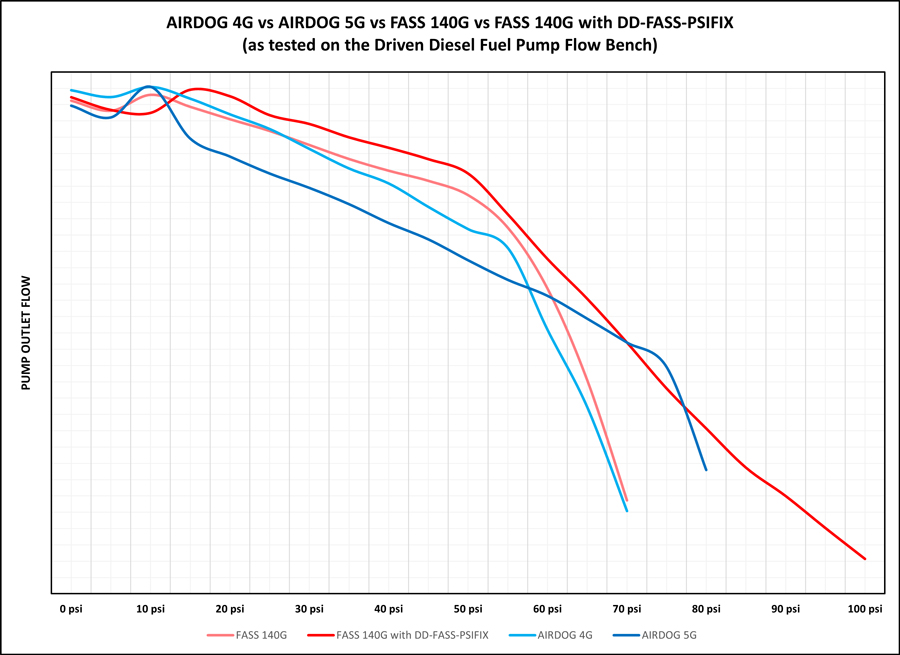

The flow charts below represents some of the results from our flow bench work. This testing revealed to us why we had some issues with some FASS or AirDog pumps, including pumps that had been sent back to the manufacturer and were deemed to be "within spec", but wouldn't perform correctly upon being installed in a customers vehicle.

In the above charts, the colors represent each configuration as follows:

- LIGHT RED : FASS 140G with FASS 75psi Regulator Spring

- DARK RED : FASS 140G with Complete Driven Diesel FASS Regulator Kit

- LIGHT BLUE : AIRDOG 4G Set At 75psi

- DARK BLUE : AIRDOG 5G Set at 75psi

As you can see from the charts above, all 4 configurations operate similarly up to about 50-55psi. As the pressure increases, the flow in GPH drops (normal for fuel pumps), some configurations drop more than others. What we ended up discovering, particularly with the AirDog 4G (new with good o-rings) and the FASS 140G (with just the 75psi spring) was that these pumps experienced a rapid loss of flow as the pressure approached the typical Regulated Return setpoint of 65psi (even with the pump regulator set to 75psi). You can see the loss of flow pretty clearly in the LIGHT RED and LIGHT BLUE lines above. The AirDog 5G, with its diaphragm style regulator, did a much better job of keeping the flow rate up to the internal regulator setpoint, but then flow drops off significantly after (dark blue line).

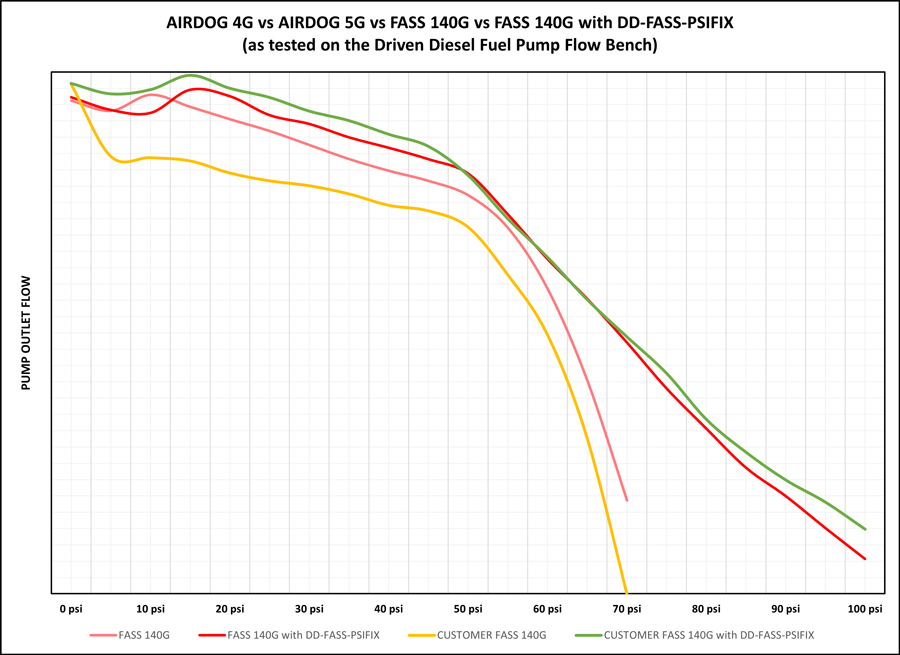

The last pump we tested was the Customer Supplied FASS 140G pump that was struggling to hold pressure in a 6.0L with a set of 155cc injectors (barely over stock). This pump would drop to 20-25psi under heavy throttle, despite getting a new pump tower from FASS, and then being sent in to FASS to be tested (confirmed to be "in spec") by FASS.

In the first test (yellow line), we ran the customers pump with the Return Fitting and 75psi Spring that we ran in our own test pump (to ensure that our test results would be as comparable to our pump as possible). If you compare the customers pump (yellow line) to our test pump (light red line), there is CLEARLY a flow difference that explains why this pump wasn't holding pressure in the truck. After seeing (2) different FASS pumps exhibit significant pressure drop at different points using the EXACT SAME regulator fitting and spring, I got curious and started poking around online to see if anyone else was having similar complaints. In doing so, I came across THIS VIDEO of how FASS performs a flow test on their pumps.

At 5:30 into the video, Brad notes that they block off the return line from the FASS pump when flow testing the pumps on the bench, so I grabbed a cap and retested the pump...sure enought, the flow rate at 65psi (the pressure we care about in 7.3L/6.0L trucks with Regulated Returns) NEARLY DOUBLED! Clearly the pump was capable of significantly more flow than we were seeing on our test bench, or our customer was seeing in his 6.0L. Here's the problem...this is NOT A REAL WORLD flow rate because customers DO NOT run FASS pumps in their trucks with the return port capped! The return port is an important part of the Air Removal functionality, capping it turns the FASS (Fuel Air Separation System) into just another fuel pump with filters. As a result, I spent some time developing the Driven Diesel DD-FASS-PSIFIX kit, which RETAINS the Air Removal functionality of the FASS pump, but addresses what I believe is an inconsistency in tolerances within the regulator portion of FASS pumps. The dark red and green lines in the above chart are the flow test results of our pump and the customers pump with the PSIFIX kit installed, and interestingly, the customers pump that flowed less than our pump with just the 75psi spring actually outflowed our pump with the same PSIFIX configuration installed.

It should also be noted, for the sake of being completely transparent and accurate, that the FASS pump only operated at its rated 140gph at or near "Free Flow" (0-20psi). This was with both a 45psi and 75psi spring in the FASS pumps internal regulator.

The AirDog 4G pump

never reached the rated volume of 165gph, even with the internal regulator set at 45psi. The AirDog 5G pump did exceed 165gph at 0psi with the internal regulator at 45psi, but fell short of the rated volume with the regulator at 75psi. Both pumps are under 100gph at the 65psi that we desire for 7.3L or 6.0L trucks.

As a final note regarding the accuracy of our flow bench, one of the many fuel pumps we tested was the 41401-1 from Fuelab. Fuelab includes a pump specific flow and amp draw chart with each pump. Our test results after running the 41401-1 pump through our bench were within 5%

across the board with the flow chart supplied by Fuelab. That's a margin of error that could easily be the difference in the style of flow meter, fittings used, tank supply connection used, etc. It certainly gave us a lot of confidence in the accuracy of the bench we built.

Based on our flow bench testing, we are most comfortable recommending that either the FASS 140G Pump (with our DD-FASS-PSIFIX kit), or the AirDog 5G, be kept to injectors smaller than 300cc (7.3L or 6.0L). Because the 6.0L is generally run to higher engine RPM, the same size injector will require more GPH of fuel as compared to a 7.3L. I believe that both pumps should handle 300s in a 7.3L fairly easily, while 300cc is likely an absolute maximum to consider with either of these pumps in a 6.0L application. If the build is purely high performance, and the injectors will be 300cc or larger, either a larger FASS pump (220G or 240G) or another high volume option (like the Driven Diesel High Volume Fuel Delivery Kits) should be considered. Maximum Injector Size supported is a comparison between the GPH of the delivery pump at 65psi and the amount of fuel used at WOT at a particular RPM, with the assumption that the tuning is emptying the fuel injector.

So which pump do we recommend? Now that we KNOW how these pumps act, and how to configure each one to work with our Regulated Return kits, we can comfortably recommend EITHER PUMP to customers that prefer this type of system over one of our Driven Diesel High Volume Fuel Delivery Kits. In the AirDog line, we have a strong preference for the 5G over the 4G pumps, just because the 5G won't need the regulator o-ring rebuilds, and the diaphragm regulator just works better than the 4G style. With the FASS pumps, we just let customers know that they will more than likely need to get our DD-FASS-PSIFIX kit, which comes with instructions that guide them through a stepped approach, starting with just the spring and only progressing to the use of every piece if necessary. As I mentioned previously, we believe that both product lines are producing the best quality products they ever have, that they have both overcome their issues of the past.

Finally, it should be noted that FASS does allow the use of the 75psi regulator spring in ONLY the 140G pump without any warranty concerns. They do NOT warrant the use of the higher pressure spring in any pump larger than 140G, and they may not honor the warranty on the pump with the extra fitting in our DD-FASS-PSIFIX kit. We have this disclaimer on the product page of our website as well. Use of the PSIFIX kit is AT YOUR OWN RISK, but in the case of some FASS pumps where nothing else has worked, may be the best solution.

If you are in the middle of a build and still have questions about which pump to use, how much pump you need, etc...don't hesitate to reach out to us via phone (623-582-4404) or email (sales@strictlydiesel.com).

Author: Dennis Schroeder - Co-Owner of Strictly Diesel

Dennis has been Designing, Building and Supporting Aftermarket Fuel Systems for 7.3L and 6.0L Powerstrokes since 2001.