NOTE: Articles in this series were written in an order that might make "skipping around" confusing. If you didn't start at the beginning, you might want to CLICK HERE.

NOTE: Articles in this series were written in an order that might make "skipping around" confusing. If you didn't start at the beginning, you might want to CLICK HERE.Trial and error are a fine way to figure some things out, we've all done it that way at some point. That's pretty much how the 7.3L/6.0L Powerstroke aftermarket has figured out what fuel pumps will support what injectors for years, for a number of reasons. First of all, not every pump manufacturer publishes flow data, some rate their pumps by Horsepower or a description like "Mild to Moderate", etc. Even the ones that do provide flow rates aren't always giving useful information. After years of doing fuel system technical support, and years of reading all kinds of different fuel pump recommendations online, we decided that it was time to collect some REAL DATA. It was time to build a Fuel System Flow Bench and really KNOW which pumps flow how much, which pumps do or don't meet their rated output, exactly how all of these different pumps flow relative to each other (on the same bench with the same standards), and what injector each pump really supports.

To construct the bench, we had to purchase a calilbrated flow meter (reads in Gallons Per Hour), which was mounted to the bench with 18" of straight inlet and outlet tubing to ensure that there weren't any bends to disrupt the flow near the meter. The inlet end of the flow meter assembly was plumbed to whatever fuel pump configuration we were measuring. If that was a system like a FASS or AirDog with built in filters, the pump inlet was connected directly to the fuel tank and the pump outlet was connected directly to the flow meter. If we were testing a raw pump like the OEM Bosch or a Fuelab, the pump inlet was connected to a filter head with a Baldwin BF1252 pre-filter, and the the pump outlet was connected to a filter head with a Baldwin BF7633 post-filter, because this is how it would be installed in the truck (and what good is the data if it isn't "Real World"). The fuel tank to pre-filter was always connected through a Driven Diesel 5/8" pickup tube and 5/8" hose. The pre-filter to fuel pump hose was either 3/8" or 5/8", depending on either the pump being tested, or whether we were testing the impact of small suction line on bigger pumps. The pump to post-filter and post-filter to flow meter plumbing was all 3/8" to match how we typically plumb these trucks.

The pumps were all powered by a benchtop adjustable 12v power supply capable of handling 100A of current. This power supply allowed us to adjust the voltage to the pumps in 1/100th of a volt increments (yes, 2 decimal places), and it measured amp draw right on the power supply. This allowed us to test the pumps in the most identical situation possible, and also to test how each pump behaved at lower voltages (like when the truck batteries or alternator aren't working optimally).

The bench also featured both an adjustable fuel pressure regulator (Fuelab of course) and a separate manually controlled ball valve so that we could find the maximum flow rate at any given pressure. In order to monitor the entire system, the flow bench incorporated 4-5 4" diameter Liquid Filled Process Gauges (depending on the specific tests being performed) in both Pressure (psi) and Vacuum (inHg) versions. We used the large gauges so that we could see small changes in the needle readings, and so that we could very precisely make pressure adjustments to keep the tests as equal as possible. Obviously digital gauges would have been preferrable, but the project was already getting expensive and the 4" process gauges proved to be accurate enough for what we needed.

Lastly, most manufacturers run their pumps with "Test Fluid". In an effort to provide the most accurate results relative to what we work on, we ran our bench on 100% Diesel #2, again seeking the more "Real World" data.

At the end of all of this testing, we now have pump flow data sheets for every pump we put through the bench. Those data sheets give us a pump flow curve from 0psi to 100psi in 5psi increments at 13.5v, along with the amp draw at every point. They also give us a voltage to flow curve from 10.0v to 14.0v at 65psi, so we know exactly what each pump does when the voltage drops. We also took IR temperature measurements of pump motors and made notes about pump noise or anything else of interest as we tested each pump.

We purchased EVERY pump we tested from whatever supplier/distributor we would normally use for that product line. We did not inform any manufacturers that we were testing pumps, we didn't ask for any free pumps, we wanted regular product from the normal supply chain. The only exception to this was the Aeromotive 11802 pump, which was sent to us by Nate Bailor from Unlimited Diesel because he heard about what I was doing and wanted to know how the pump compared to the specs he got from Aeromotive.

List of Pumps Tested (in no particular order):

• Bosch 69136 (7.3L OEM Pump)

• Dual Bosch 69136 (as sold in Driven Diesel kits)

• Fuelab 41401-1 on Reduced Speed (as sold in Driven Diesel Kits)

• Fuelab 41401-1 on Full Speed (as sold in Driven Diesel Kits)

• FASS 7.3L/6.0L 140G Signature Series with 75psi Spring

• AirDog 7.3L/6.0L DF-165 4G (adjusted to 75psi)

• AirDog 7.3L/6.0L DF-165 5G (adjusted to 75psi)

• OEM 6.0L Powerstroke Fuel Pump

• OEM 6.7L Powerstroke Fuel Pump

• Walbro GSL392

• Bosch "044"

• Bosch "200"

• AEM 380LPH

• Aeromotive 11802 (adjusted to 70psi)

• AirTex E2236 7.3L Direct Replacement Pump

When we started this project, the point was to have flow data for all of the popular pumps that was truly "relative" because it all came from the same flow bench and testing procedures. We 100% accomplished that goal. At the same time, we were thinking that there had to be a way to use this data to properly recommend fuel delivery products or kits to our customers...which then involves needing to know what size injectors they are running and how they use their truck. The following charts represent the most common 7.3L and 6.0L fuel injector sizes, how each of the different pumps tested and which pumps will support which injectors. There may be other factors that affect pump performance or selection, particularly if your combination is outside of the parameters of these charts (larger injectors, higher RPM, etc)...but this should cover the needs of 99% of 7.3L and 6.0L performance builds.

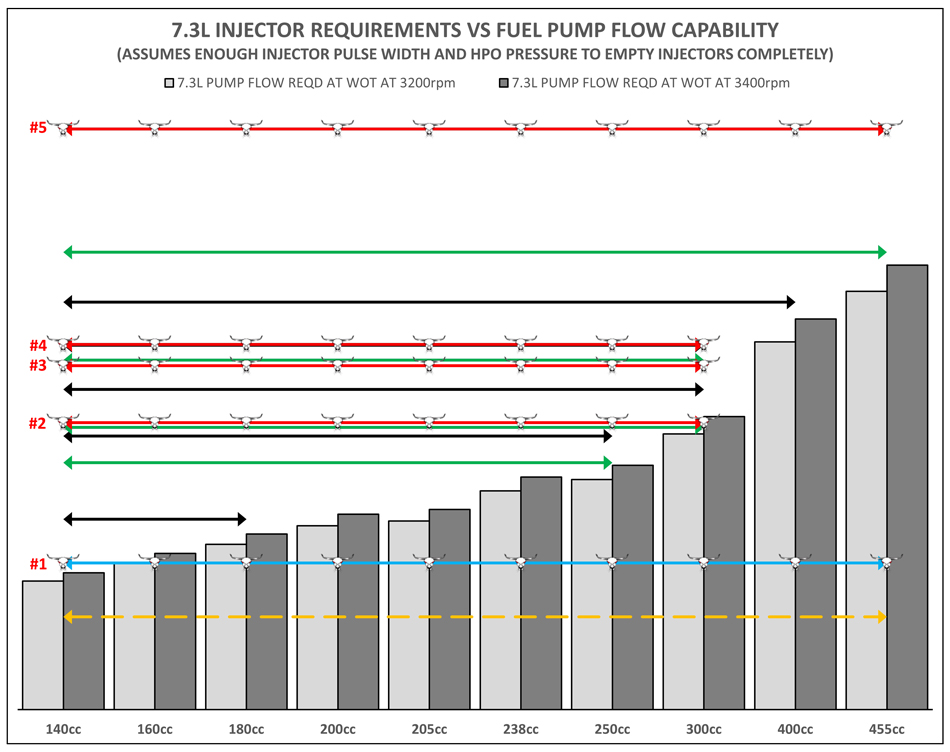

7.3L FUEL INJECTOR AND FUEL PUMP DATA CHART AND DISCUSSION

7.3L Injector Requirements (WOT at Specified RPM) and Fuel Pumps that Work

The first thing to note about this chart is that the injector sizes are listed across the bottom. The corresponding light and dark grey bars represent that injectors pump flow requirement at Wide Open Throttle at the specified RPM (3200 & 3400). It is assumed that the tuning has enough injector pulse width and injection control pressure commanded to 100% empty the injector, and the controlled components (IDM, Injectors and HPOP) are working as desired. We have also added 5% to each 7.3L flow requirement value (vertical grey bars in chart) to ensure that our pump recommendations are including enough padding to maintain fuel pressure at all times. Essentially, these are "Worst Case" numbers, if your tuner doesn't ask for enough PW or your HPOP isn't maintaining pressure, and your injectors are not fully emptying, your needs will be less. Data over 3400rpm isn't provided here because 7.3L engines generally don't make any more useful power above that engine speed due to the slow injection system and terrible flow characteristics of the heads, if you are operating your 7.3L at higher RPM, your fuel requirements will be higher than what is shown here. For most people, the 3200rpm Data (light grey bar) will be what they should base their decisions on. Lets get into the other data on the chart:

NOTE : The lines with bullheads represent flow levels from Driven Diesel fuel pump kits.

- DASHED YELLOW LINE : This is an AirTex E2236 Direct Replacement Fuel Pump (for 99-03 7.3L). Based on the performance on the bench, we HIGHLY RECOMMEND avoiding this pump at all costs, even if your truck is stock. This pump did not flow well enough to support Stock injectors at WOT. It is possible that this was a fluke junk pump, we did NOT order another one to test, we didn't feel like anyone would really care.

- #1 - LIGHT BLUE LINE WITH BULLHEADS : This is a Bosch 69136 Fuel Pump that is used in 99-03 7.3L trucks as well as the DRIVEN DIESEL 94-97 OBS Electric Fuel System kit. This pump supports up to 160cc injectors at 3200rpm fully, and up to 180cc injectors in situations where the tuning and components are not completely emptying the injector. This line is carried out to the far right just to show how much this pump DOES NOT actually support.

- SHORT BOTTOM BLACK LINE : This is a stock 6.0L fuel pump, it is just here to show the slight difference in flow because we've been asked about running this pump in a 7.3L by a few people, we personally don't think it's worth messing with.

- #2 - BOTTOM RED LINE WITH BULLHEADS : This is the DRIVEN DIESEL DUAL BOSCH High Volume Fuel Delivery System. This kit will support up to 300cc 7.3L injectors.

- #3 - 2nd RED LINE WITH BULLHEADS : This is the DRIVEN DIESEL FUELAB High Volume Fuel Delivery System (with the pump run at LOW SPEED per Fuelab instructions). This kit will support up to 300cc 7.3L injectors (400cc if not getting fully emptied or switched to full speed).

- #4 - 3rd RED LINE WITH BULLHEADS : This is the DRIVEN DIESEL BOSCH "200" High Volume Fuel Delivery System. This kit will support up to 300cc 7.3L injectors.

- #5 - TOP RED LINE WITH BULLHEADS : This is the DRIVEN DIESEL FUELAB High Volume Fuel Delivery System (with the pump run at FULL SPEED per Fuelab instructions). This kit will support 455cc+ 7.3L injectors.

- OTHER BLACK/GREEN LINES : Other Fuel Pumps We Tested

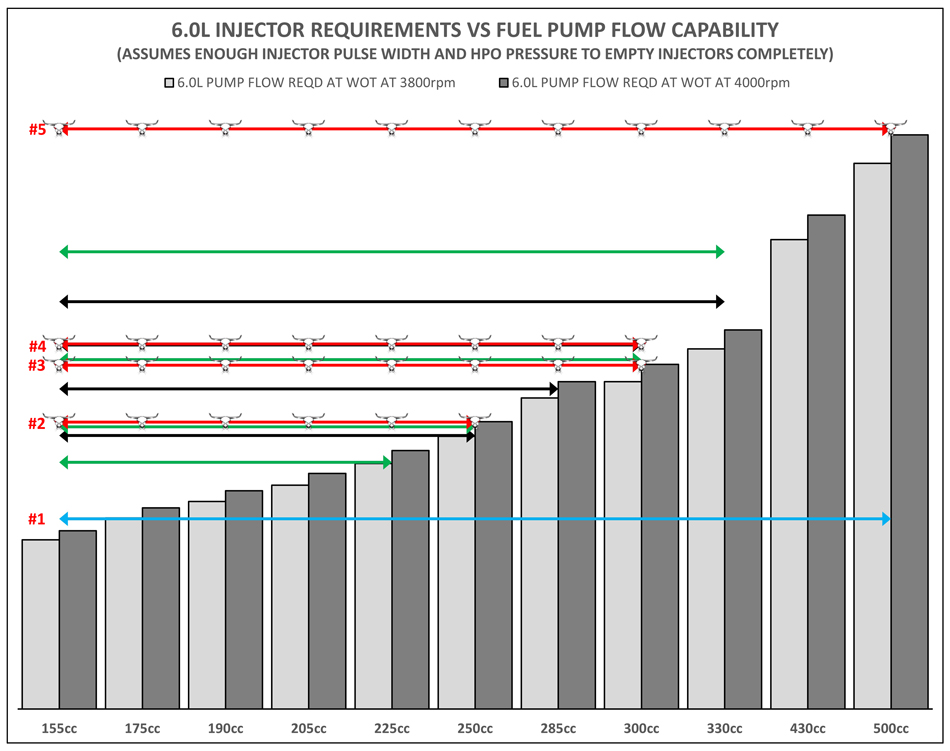

6.0L FUEL INJECTOR AND FUEL PUMP DATA CHART AND DISCUSSION

6.0L Injector Requirements (WOT at Specified RPM) and Fuel Pumps that Work

The first thing to note about this chart is that the injector sizes are listed across the bottom. The corresponding light and dark grey bars represent that injectors pump flow requirement at Wide Open Throttle at the specified RPM (3800 & 4000). It is assumed that the tuning has enough injector pulse width and injection control pressure commanded to 100% empty the injector, and the controlled components FICM, Injectors and HPOP) are working as desired. We have also added 5% to each 6.0L flow requirement value (vertical grey bars in chart) to ensure that our pump recommendations are including enough padding to maintain fuel pressure at all times. Essentially, these are "Worst Case" numbers, if your tuner doesn't ask for enough PW or your HPOP isn't maintaining pressure, and your injectors are not fully emptying, your needs will be less. Data over 4000rpm isn't provided here because 6.0L engines generally don't make any more useful power above that engine speed. If you are operating your 6.0L at higher RPM, your fuel requirements will be higher than what is shown here. For most people, the 3800rpm Data (light grey bar) will be what they should base their decisions on. Lets get into the other data on the chart:

NOTE : The lines with bullheads represent flow levels from Driven Diesel fuel pump kits.

- #1 - LIGHT BLUE LINE : This is the OEM HFCM used in 03-07 6.0L trucks. This pump supports up to 175cc injectors at 3800rpm fully, and up to 190cc injectors in situations where the tuning and components are not completely emptying the injector. This line is carried out to the far right just to show how much this pump DOES NOT actually support.

- #2 - BOTTOM RED LINE WITH BULLHEADS : This is the DRIVEN DIESEL DUAL BOSCH High Volume Fuel Delivery System. This kit will support up to 250cc 6.0L injectors.

- #3 - 2nd RED LINE WITH BULLHEADS : This is the DRIVEN DIESEL FUELAB High Volume Fuel Delivery System (with the pump run at LOW SPEED per Fuelab instructions). This kit will support up to 300cc 6.0L injectors (330cc if not getting fully emptied, or up to 500cc if switched to full speed).

- #4 - 3rd RED LINE WITH BULLHEADS : This is the DRIVEN DIESEL BOSCH "200" High Volume Fuel Delivery System. This kit will support up to 300cc 6.0L injectors.

- #5 - TOP RED LINE WITH BULLHEADS : This is the DRIVEN DIESEL FUELAB High Volume Fuel Delivery System (with the pump run at FULL SPEED per Fuelab instructions). This kit will support 500cc 6.0L injectors.

- OTHER BLACK/GREEN LINES : Other Fuel Pumps We Tested

You may have noticed that our DRIVEN DIESEL DUAL BOSCH High Volume Fuel Delivery System will support 300cc injectors in a 7.3L, but only 250cc injectors in a 6.0L. This is because of the additional 600rpm the 6.0L is calculated to be running, due to having faster injectors and better airflow. Increasing the RPM means more injector firings per minute, which translates to more fuel used per minute, which means that the same size injector requires more fuel volume at a higher RPM to prevent pressure drop.

This flow bench work proved to be extremely interesting, and surprising in some ways. It is "Normal" for typical fuel pumps to lose volume as the fuel pressure goes up, for example...but it was surprising how drastically different some of the pump curves were when compared to what we felt were "Similar" pumps. Several pumps performed exactly as advetised, which was good in that it validated our flow bench configuration as much as it validated the pump performance. For example, the flow and amp draw curves for the Fuelab 41401-1 pump matched the paperwork that Fuelab includes in the box perfectly.

Even more interesting was the behavior of the pumps with built-in regulators, which show a similar downward trend in flow as the pressure goes up...until we started getting close to where the regulator opens and the pressure dropped significantly. Having the pumps on the flow bench was instrumental in figuring out exactly how these need to be set to maintain the best flow possible at the typically desired fuel pressure of 65psi AT THE ENGINE.

There were a few pumps that didn't live up to their marketing with respect to flow rates. It appears that some pump manufacturers have chosen to advertise the "Free Flow" flow rate, rather than the flow rate at operating pressure. While this was disappointing, those pumps did still flow enough to support fairly significant injector sizes, so we aren't calling them out by name. We think they should change how they rate the pumps, or be more forthcoming and provide full pump flow curves, but we aren't holding our breath.

If you were expecting a full release of all of the specific data on every pump, we're sorry to disappoint. We've got far too much time and money invested in this testing to just hand that data over to competitors. At it sits right now, the charts and pump list above already give away plenty of useful information.

It should be noted that the pump flow matching to injector flow requirements illustrated in these charts is based entirely on how much fuel each injector can flow at a given RPM. In application, there are other factors that can come into play, not the least of which is the flow capability of the cylinder head fuel rails themselves. As such, while we had the flow bench up and running, we also put a 7.3L and 6.0L head through the paces to see what they actually flow. That data will be presented in the next article.

Author: Dennis Schroeder - Co-Owner of Strictly Diesel

Dennis has been Designing, Building and Supporting Aftermarket Fuel Systems for 7.3L and 6.0L Powerstrokes since 2001.