NOTE: Articles in this series were written in an order that might make "skipping around" confusing. If you didn't start at the beginning, you might want to CLICK HERE.

NOTE: Articles in this series were written in an order that might make "skipping around" confusing. If you didn't start at the beginning, you might want to CLICK HERE.During the same period of time that we were all testing different variations of engine fuel system plumbing (Regulated Return work), another F-D.com member named Mark Hutchison (hutchinaugusta) made an equally, if not bigger discovery in the fuel delivery system underneath our trucks. Mark got curious and installed a section of clear tubing at the inlet of his electric fuel pump, and very quickly spotted a pretty significant problem in how things were working. You need to keep in mind that these trucks were all fairly new at the time, just a couple of years old at the most, so what we saw wasn't the result of age and failure, it was just an unexpected problem in performance and design.

If you have not guessed by now, what Mark saw was a pretty significant amount of air travelling to the pump from the tank. Enough that he needed to explore further and figure out where it was coming from, and why. What Mark found, and what tens of thousands have since been able to reliably duplicate through commercially available kits like ours, or on their own, were noteable issues both inside and outside of the fuel tank. Issues that were either allowing air into the system, or "releasing entrained air" that was already mixed into the fuel.

SOME QUICK DEFINITIONS: before we go any further, I wanted to quickly cover the 2 types of air that get discussed when talking about diesel fuel systems.

- FREE AIR : free air is, for the purposes of these discussions, visible air bubbles in the fuel. Using a clear hose on the fuel system, free air can be easily seen by lighting up the hose with a flashlight, and may be in the form of obvious large bubbles or may look more like "flecks" floating in the fuel because the bubbles are so small (but still visible). It can also be seen floating at the top of the fuel tank as foam. This is the easiest air to deal with.

- ENTRAINED AIR : entrained air is air that is so "mixed into" the fuel that it is no longer visible. It is air that is now "in solution" with the fuel. Entrained air is much harder to remove.

Before I get back to what Mark discovered, and how it is fixed, I wanted to also address why air in the fuel is actually problematic. You can find some pretty good videos by companies like FASS and AirDog that show animations of these problems by searching YouTube, this will be a more simple and short explanation. In a nutshell the issue is three-fold: air is compressible, air does not make power and air does NOT work to lubricate or cushion moving metal parts.

The compressibility of air is problematic when you consider that some diesel fuel injectors/injection pumps have a piston with the sole job of forcing fuel through the injector nozzle on command from the computer or based on pump timing. When that piston starts to move, if there is air in the fuel cavity, some of the piston travel will be wasted compressing the air instead of moving the fuel through the nozzle, resulting in delayed injection timing, loss of performance, loss of economy, etc. This issue may be a little less critical in common rail systems where the fuel is constantly at injection pressure and the injector is simply an electronically controlled on/off valve.

Additionally, any space being taken up by air is space in the fuel system that should have been filled with fuel. Since diesels are throttled on the amount of fuel that is injected, that missing fuel that was replaced by air can result in unbalanced operation or an overall loss of power. How much depends on just how much air made it to the injector(s).

Lastly, there are internal parts of fuel injectors that are lubricated and/or cushioned by the presence of diesel fuel. If some of that fuel is replaced with air, the risk of moving parts colliding without cushion, or rubbing against each other without lubrication increases. Over time, this can result in premature wear or failure in the injectors.

The compressibility of air is problematic when you consider that some diesel fuel injectors/injection pumps have a piston with the sole job of forcing fuel through the injector nozzle on command from the computer or based on pump timing. When that piston starts to move, if there is air in the fuel cavity, some of the piston travel will be wasted compressing the air instead of moving the fuel through the nozzle, resulting in delayed injection timing, loss of performance, loss of economy, etc. This issue may be a little less critical in common rail systems where the fuel is constantly at injection pressure and the injector is simply an electronically controlled on/off valve.

Additionally, any space being taken up by air is space in the fuel system that should have been filled with fuel. Since diesels are throttled on the amount of fuel that is injected, that missing fuel that was replaced by air can result in unbalanced operation or an overall loss of power. How much depends on just how much air made it to the injector(s).

Lastly, there are internal parts of fuel injectors that are lubricated and/or cushioned by the presence of diesel fuel. If some of that fuel is replaced with air, the risk of moving parts colliding without cushion, or rubbing against each other without lubrication increases. Over time, this can result in premature wear or failure in the injectors.

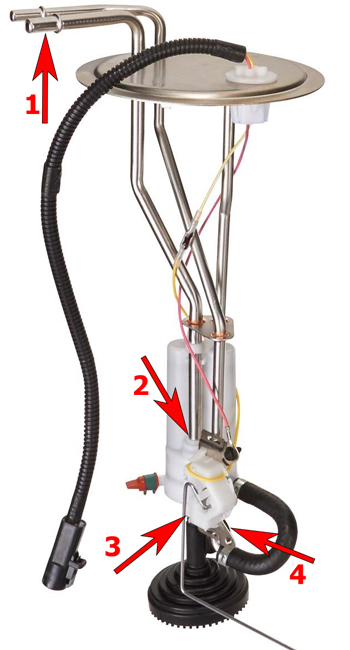

Upon dropping the fuel tank and removing the fuel level sending unit, Mark found himself looking at the DTRM (Diesel Thermal Recirculating Module), over the years we've just shortened it to "The Mixing Chamber". The DTRM is the white plastic canister that is located in the lower portion of the pickup tube assembly. Its purpose is to mix warmed fuel from the engine with cold fuel coming from the tank, as well as provide a set of fine screens to keep debris from getting picked up in the fuel tank and delivered to the fuel pump. While neither of these functions are terribly problematic, the implementation of the DTRM is one of the largest sources of air intrusion in the Powerstroke fuel system. The #2 arrow is pointing at the junction between the S.S. pickup tube and the plastic body of the DTRM. Just inside this port is an o-ring that seals the tube to the plastic body of the DTRM. As fuel levels drop, this part of the unit will be exposed to air in the fuel tank, we have discovered that it takes very little for air to get drawn in passed an o-ring like this.

Upon dropping the fuel tank and removing the fuel level sending unit, Mark found himself looking at the DTRM (Diesel Thermal Recirculating Module), over the years we've just shortened it to "The Mixing Chamber". The DTRM is the white plastic canister that is located in the lower portion of the pickup tube assembly. Its purpose is to mix warmed fuel from the engine with cold fuel coming from the tank, as well as provide a set of fine screens to keep debris from getting picked up in the fuel tank and delivered to the fuel pump. While neither of these functions are terribly problematic, the implementation of the DTRM is one of the largest sources of air intrusion in the Powerstroke fuel system. The #2 arrow is pointing at the junction between the S.S. pickup tube and the plastic body of the DTRM. Just inside this port is an o-ring that seals the tube to the plastic body of the DTRM. As fuel levels drop, this part of the unit will be exposed to air in the fuel tank, we have discovered that it takes very little for air to get drawn in passed an o-ring like this.Before I cover the two remaining large sources of air intrusion, I want to cover two smaller possible sources that are less problematic. Arrow #3 is pointing at the junction between the black pickup screen assembly and the male nipple on the bottom of the DTRM. Should this clamp be loose, or the black plastic tube develope a crack, air can be sucked into the system when the fuel level is low enough. In the early days, this wasn't all that big of a problem because the trucks were new. Today, we see a LOT of failure in the black plastic pickup screen, many times they are broken into numerous pieces that are floating around the fuel tank, and the vehicle runs out of fuel with 1/4 tank showing on the gauge. Failures with the pickup screen have become so common with the age of these trucks that many people today believe that THIS is reason for THE HUTCH MOD, but read on and you will see that pickup screen failure had nothing to do with it, it just worked out that THE HUTCH MOD is a good solution for that problem as well.

The same goes for arrow #4, which is pointing at the (not visible in this picture) blockage valve on the side of the pickup screen. This valve exists to provide a place for fuel to enter the system in the event that something completely blocks the bottom of the pickup screen. Unfortunately, we have seen this valve deformed and not making a seal against the body of the pickup screen, allowing air to enter the system any time the fuel level was low enough or the fuel sloshed around and uncovered the valve.

Through multiple experiments with the clear hose, Mark also discovered that there was a significant amount of air coming from the arrow #1 location. Like the interface between the pickup tube and the DTRM, the quick disconnect fitting that connects the sending units pickup tube to the suction line going along the frame to the pump uses o-rings to seal...and those o-rings don't do a great job of preventing small amounts air from being sucked into the system when the pump is running. The o-rings seal well enough to prevent fuel leaks, and when the pump isn't running, they seal well enough to prevent the system from losing prime, but under suction from the pump, they were allowing enough air into the system that it was visible in the clear hose.

Finally, Mark noticed that the inlet at the OEM fuel pump (not pictured here) also used the same o-ring sealed quick disconnect type fitting. By the time he was done experimenting with the different locations he felt were allowing air into the system, he had replaced the quick disconnects at the pump and #1 with simple and effective hose and clamps, he removed the DRTM completely, extended the pickup tube with a compression fitting, made sure that the pickup screen connection was secure and plugged the side valve of the pickup screen with a freeze plug and a clamp. The results were nothing short of shocking to everyone that followed his lead to verify the work. These modifications ARE what has been known as THE HUTCH MOD for over 20 years now, and they are still being performed today by owners that are just as happy with the results as we were back then.

For as long as I can remember, our kits have included a long enough pickup tube extension that we internally cover the blockage valve on the side of the pickup screen, rather than using the freeze plug method. We also include an extended return tube that dumps fuel returning from the engine (that may have been churned up and aerated by the fuel pump or by passing through restrictive fittings or over sharp corners) away from the pickup tube, allowing any free air a chance to rise to the top of the tank without being immediately picked up by the pickup tube.

PICKUP TUBE / SCREEN NOTE: I am aware that some people have performed this modification using submersible hose for the pickup tube extension, and I don't recommend this method. The downside to using submersible hose is that you can't ensure the same ability to run the fuel tank as low as you can with the OEM pickup screen before air starts to get picked up. The flexible hose will have a natural bend and may sit pretty close to the floor of the tank, but the available surface area for it to draw fuel from will be significantly smaller and it will be far more prone to sucking air with sloshing at lower fuel levels. The OEM pickup screen serves an important purpose, and despite the occasional failures from the plastic aging, it is worth keeping it if you can. The biggest benefit is the ability to remain in contact with the floor of the tank at all times, maintaining the best ability possible to continue picking up fuel, down to the lowest fuel tank levels possible. Of course, nobody recommends running the fuel tank so low that you test it regularly, but it's nice to know that you can if you need to.

FILTRATION NOTE: since THE HUTCH MOD removes the fine screens that are part of the DTRM, we supply a spin-on filter on the outside of the tank to take their place. This ends up working much better because you don't have to go inside the tank to service the screens if they get plugged up, and the spin-on filter has much higher contaminant holding capacity, flow capability and also adds water separation. The only downside is the minimal cost of a replacement filter every 15,000 miles, not much to pay for significant peace of mind.

As a side note, I would be remiss in discussing THE HUTCH MOD without also mentioning "Harpooning" the tank as well. MaroonHarpoon (his real name has long since left my old memory) was another F-D.com member during this time, and when he dove into his tank (presumably to do the Hutch Mod), he also noticed that the fill and vent tubes extended quite a distance into the tank. He cut his fill and vent tubes shorter while he was in there, and reported back that it made getting the tank full much quicker and easier (for those of us that insist on filling into the neck). As a result, we've had the wonderful and FREE HARPOON MOD ever since.

Since my next article will also be about AIR REMOVAL devices like FASS and AirDog pumps, I want to take a minute to distinguish the difference. THE HUTCH MOD is what I prefer to call PASSIVE AIR REMOVAL. The entire purpose amounts to plugging the holes that commonly allow noticeable amounts of FREE AIR into the fuel system. It works extremely well when done correctly, provides noticeable improvement in how the engine runs and adds better filtration and water separation to the system. It is absolutely as valuable today as it was 20+ years ago when Mark figured it out.

DRIVEN DIESEL products that are related to this article:

Fuel Tank / Pre-Pump Kit (aka THE HUTCH MOD)

Standard Pre/Post Fuel Filter Kit (includes THE HUTCH MOD)

Driven Diesel also offers other fuel filter and fuel pump kits that are geared toward more "High Performance" builds. While these other kits may not include THE HUTCH MOD specific parts, this is only because they include other solutions that accomplish the same thing (fuel tank sumps and aftermarket pickup tube assemblies). Every single fuel filter kit or fuel pump kit we offer today is designed with preventing free air intrusion as a necessary function.

Author: Dennis Schroeder - Co-Owner of Strictly Diesel

Dennis has been Designing, Building and Supporting Aftermarket Fuel Systems for 7.3L and 6.0L Powerstrokes since 2001.